Anytime a part of the human body contacts a flow of electricity, it can become part of the circuit. Depending on the amount energy in a given circuit, a person or body appendage(s) can pass part or all of the electricity resulting numbness, burns, strange/unusual sensory feelings, heart fibrillation, and/or heart attack.

Almost all of the electrical equipment we work with is capable of causing electrocution if used improperly.

| Electrical Voltage | Effect |

|---|---|

| 1 mA | shock perception level |

| 5 mA | GFCI trip level |

| more than 10 mA | 'let go' threshold |

| 15 mA | muscle contraction/freezing |

| 30 mA | breathing difficulty, hard fibrillation in small children |

| 50-4000 mA | adult ventricular fibrillation |

| more than 4000mA | heart paralysis, serious tissue and organ burns |

Why worry about electricity?

Approximately 350 workers are killed in the United States each year as a result of electrical incidents. In addition to heart attack and burns these deaths can occur from falls after contact with electricity.

Please click the following link to read a summary from the Washington State Department of Labor and Industries regarding occupational burn injuries and their causes: Washington State L&I Hospitalized Burn Page.

Topics on this page:

Electrical Safety for General Industry

Please click the button below to download OSHA’s 10 hour Electrical Training Presentation for General Industry. This presentation covers:

- Common Electrical Hazards

- Personal Protective Equipment

- Hazardous Locations

- GFCI

Ground Fault Current Interrupter

A ground fault circuit interrupter (GFCI) is a device that shuts off an electric power circuit when it detects that current is flowing along an unintended path, such as through a person or water. GFCI measures the amount of current going out and coming back and cuts power if there is a 5 mA difference between the two.

GFCI outlets are required for any outlet that is within six feet of a water source. They can usually be identified by the presence of the “Test” and “Reset” buttons.

GFCI is also available in power cords. These should be used anytime there is the possibility of water coming into contact with a power cord or a piece of equipment.

At a recent safety conference an electrical worker stated that GFCI is the best lifesaving piece of equipment that has come out.

Lockout/Tagout

Lockout/Tagout (LOTO) is the prevention of hazardous energy release while servicing equipment and/or systems for worker safety.

Examples of hazardous energy include:

- Electrical

- Hydraulic

- Physical

- Thermal

Lockout/Tagout Energy Control Program

Program outlining EWU’s general lockout/tagout safety and procedures. All employees working with or near equipment/systems where the startup or release of stored energy could cause injury are required to follow this program.

Lockout/Tagout training is required prior to any jobs that require LOTO.

Lockout/Tagout Forms

This form must be used to document any training provided to employees or students. This form should be attached to any handouts or presentations given as part of the training. Training records must be maintained for a minimum of three years. Send all training records to EH&S annually to ensure appropriate retention.

Abandoned Lock/Tag Removal Form

This form must be filled out anytime a supervisor or Lockout Coordinator removes a lock or tag that was left behind. Must be signed by the employee who left the lock/tag and submitted to the Facilities Operation Manager.

Use this to record all equipment and systems that require lockout/tagout procedures.

Group Lockout/Tagout Procedure Worksheet

Fill out and use this worksheet for all group lockout/tagout procedures.

Individual Lockout/Tagout Procedure Worksheet

Fill out and use this worksheet for any individual lockout/tagout procedure that involves more than one energy source or energy isolation point.

Lockout/Tagout Equipment Specific Procedure

Every item on the Equipment Inventory Form requires a procedure. All procedures must be reviewed annually for compliance.

Tagout-Only Justification Form

Submit this form to the Facilities Operation Manager to get approval for Tagout-Only procedures.

Electrical Personal Protective Equipment (PPE)

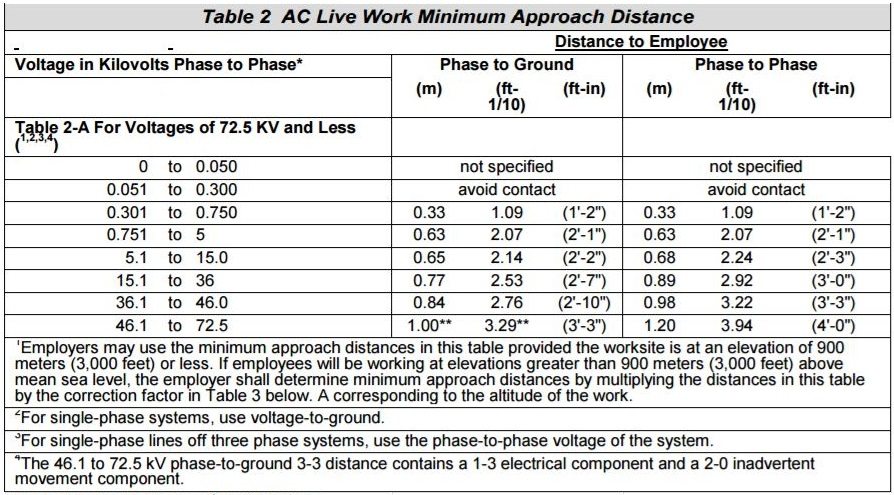

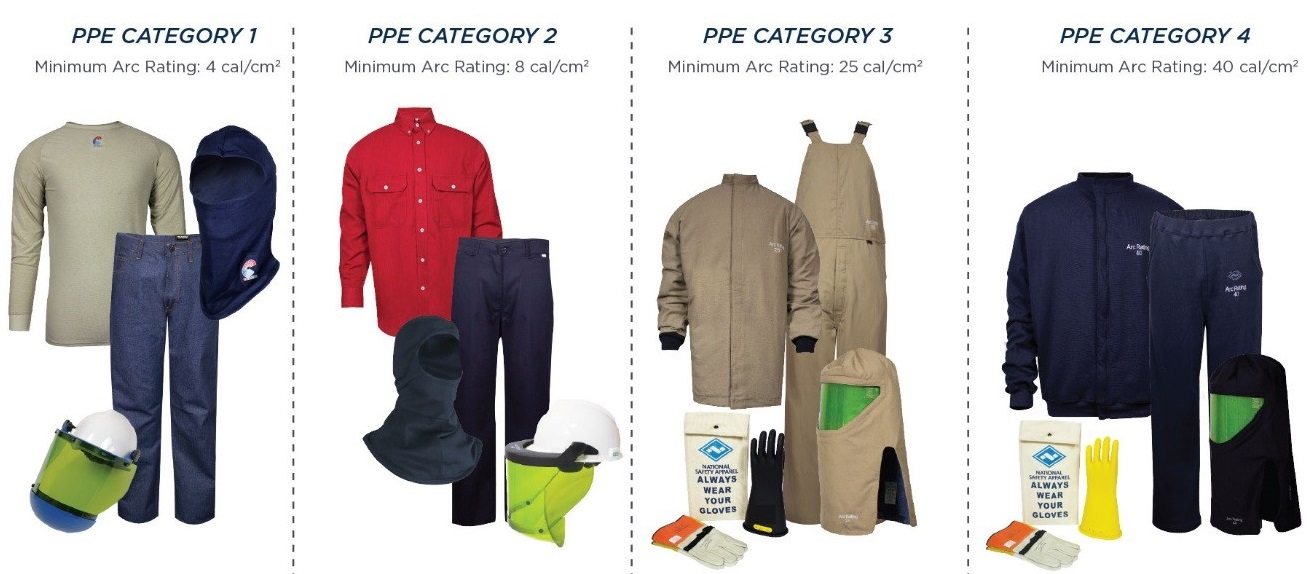

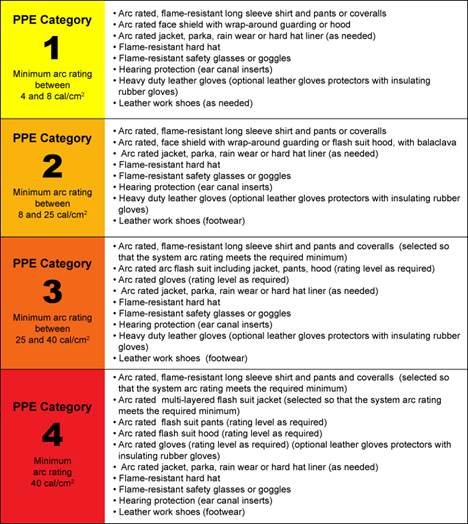

The PPE required when working with electricity will depend on the amount of energy that the worker may be exposed to.

(In 2015, NFPA 70-E was updated and removed PPE Category 0.)

Arc Flash

Arc flashes occur when energy moves through the air from an exposed live conductor to another conductor or the ground. These events generate extremely high temperatures and pressure waves in addition to the flowing electrical current.

It is estimated that between five and ten arc flashes occur every day in the United States.

Arc Flash Facts

This safety article from Creative Safety Supply covers information about arc flashes, how they can happen, and what the results can be.

“One of the biggest dangers associated with an arc flash is the extremely high temperature it can create. Depending on the situation, they can reach temperatures as high as 35,000 degrees Fahrenheit. This is one of the hottest temperatures found anywhere on earth and is actually about 4 times hotter than temperatures found on the surface of the sun.”

Arc Flash Information

This PDF (Please click the green button below), from Brandon & Clark Inc. provides information on arc flashes and electrical safety covering the topics:

- “What is an electrical arc flash?”

- “How do I calculate the danger posed by an arc flash?”

- “How do I protect myself and others from an arc flash?”